COMPANY PROFILE

We provide innovative Product Solutions for sustainable progress.NORSEN, is a worldwide leading company in wastewater & solid-liquid separation of industrial & municipal wastewater. Our featured products are Wastewater.

- Innovative Separation Technology.

- Serve best solutions for clients worldwide!

- Better World! Clean Environment!

- Quality & Satisfied Prodution.

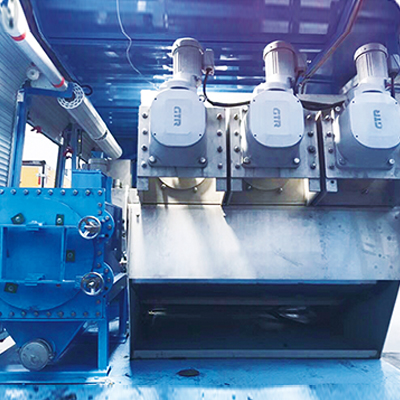

Our recent projects

We are servicing a

global clients in

more than 50

countries

Innovative Separation Technology

Keeps on innovative separation equipment research & production.

Serve best solutions for clients worldwide!

We believe each case has a better solution!

Better World! Clean Environment!

Our mission is to make the environment clean and have better world for next generation!

Quality & Satisfied Prodution

Excellence and quality is our pursuit Target!

Request a Quote

0

Years sewage&sludge experience0

Export countries0

Annual Sales Qty0

Patents of Separation tech

Multi-Disc Screw Press

Multi-Disc Screw Press

Dissolved Air Flotation

Dissolved Air Flotation

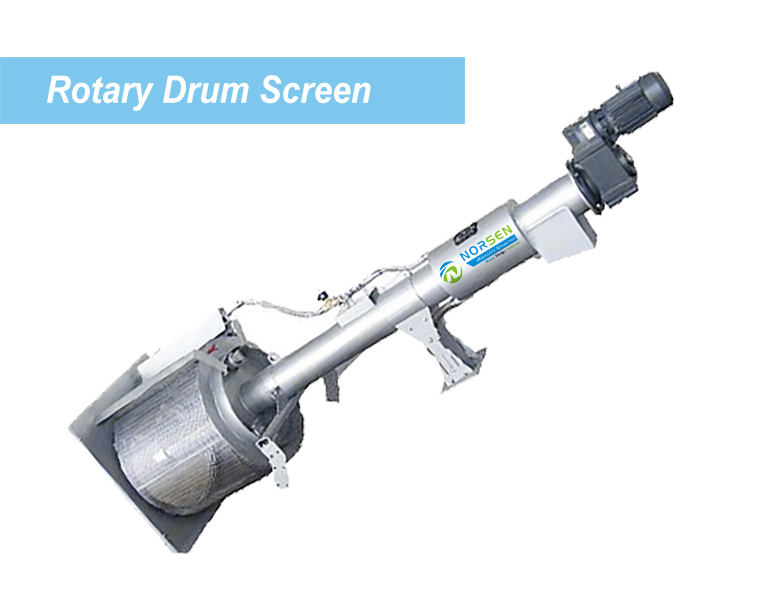

Rotary Drum Screen

Rotary Drum Screen

Mobile Sludge Dewatering System

Mobile Sludge Dewatering System

Plate Filter Press

Plate Filter Press

MBBR(Bio Media)

MBBR(Bio Media)