1. Product Applications:

① Improving standards and quality for the wastewater upgrading and reforming project;

② Carrier of wastewater treatment MBBR and biological aerated filter;

③ Biochemical treatment of water reuse,

④ New projects saving investment and land occupation planning;

⑤ River regulation for nitrogen and phosphorus removal;

⑥ Aquaculture for ammonia nitrogen removal and water purification;

⑦ Biofilm packing for biological deodorization tower;

⑧ Application industry: municipal, electric power, pharmaceutical, chemical, electroplating, metallurgy, medical treatment, machinery, paper making, printing and dyeing, food processing, aquaculture, etc;

⑨ With the continuous improvement of products and deepening of application, the application field of PE bio-suspended filler will be more and more broad.

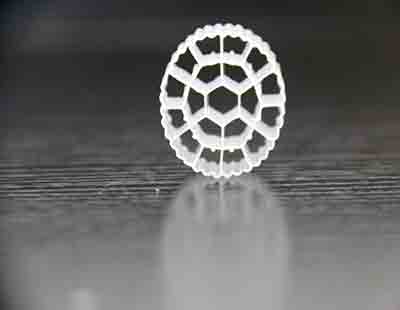

MBBR(Fluidized bed biofilm reactor)(Active suspended biological filler)is a new bioactive carrier,which uses scientific formula. According to the different nature of sewage,a variety of trace elements which are beneficial to the fast adhesion and growth of microorganisms are fused into the polymer material.It is modified and constructed by special process, which has the advantages of large specific surface area, good hydrophilicity, high biological activity, fast film hanging, good treatment effect and long service life.

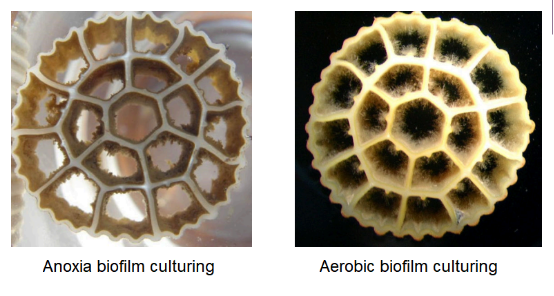

carrier is free to rotate under the tumbling of the mixture in the reactor, and the biofilm is in full contact with the contaminants in the water body and decomposed to purify the water. The stirring of the mixture and the carrier are realized by aerobic aeration or anaerobic stirring.

1. Main Features Of Active Biological Fillers:

(1). Designed according to fluid mechanics, enhanced surface adhesion, specially designed geometry, with a large effective specific surface area;

u The filler is made of macromolecular material, which is modified and has strong impact resistance;

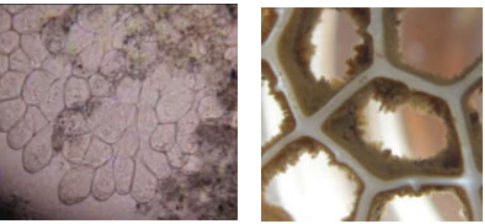

u Advanced surface treatment technology is more conducive to the adhesion growth of microorganisms;

u The special structure and geometric size of packing improve the mass transfer efficiency of the system.

(2). The packing has large specific surface area, large adhesion biomass and high abundance

u With a large specific surface area, providing support for a large number of microbial attachment growth

u It is beneficial to the growth of various microorganisms, not only provides space for the growth of heterotrophic bacteria, but also creates conditions for the growth of autotrophic bacteria, laying a solid foundation for biological nitrogen and phosphorus removal.

(3). No need for brackets, easy fluidization, energy saving

u proper weight(0.97~0.98 before hanging membrane,1 after hanging membrane),the filler is in a floating state when the gas is stopped, and is in a suspended fluidized state under aeration to minimize the energy consumption;

u The fluidization of the filler increases the impact and cutting of the bubbles, improves the utilization of oxygen, and reduces the energy consumption of the aeration. Under the same conditions, the aeration can be reduced by more than 10%.

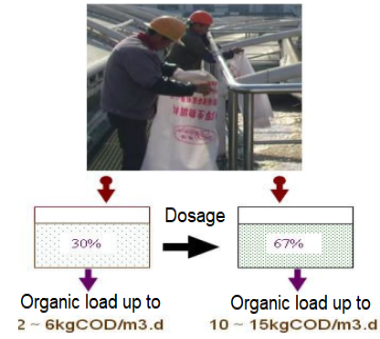

(4). Save space, increase processing capacity and effect by increasing filling rate, no need to add new structures.

2. Runing State In Water

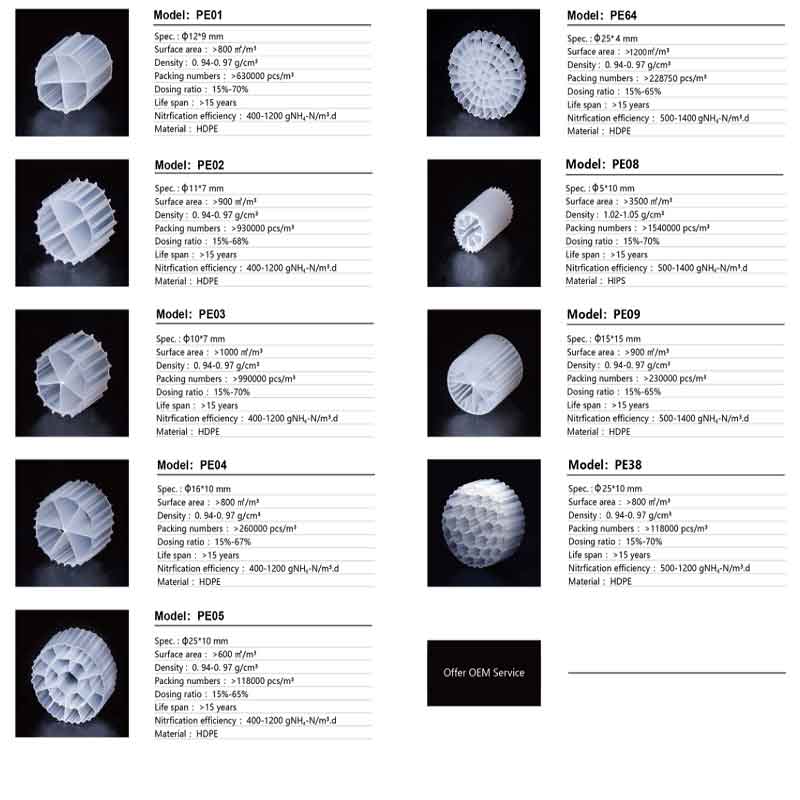

3 Technical sheet

Phone: +86 138 1256 5699

Email: jenny@norsenep.com;sales@norsenep.com

Add: Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Add: Xibei H-Tech Park Wuxi Jiangsu China