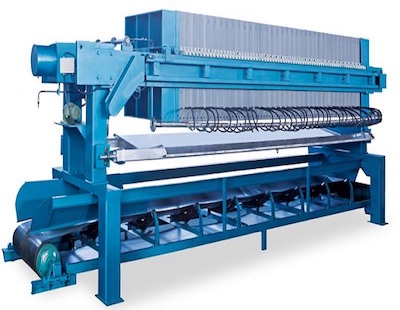

Filter press is a machine that applies mechanical force on one side of the filter medium to achieve filtration, and is mainly used for solid-liquid separation of sludge (water).

Application industry

Suitable for sludge dewatering in wastewater treatment processes in urban sewage treatment plants, pharmaceuticals, electroplating, papermaking, leather, printing and dyeing, metallurgy, chemicals, slaughter, food, wine making and environmental protection projects. It can also be used for solid-liquid separation in industrial production. , It is the ideal equipment for environmental management and resource recovery. It can also be applied to solid-liquid separation or liquid leaching in industrial production.

Working principle

The water-containing sludge is transported by the sludge pump to the sludge mixing tank, and at the same time, the coagulant is added for thorough mixing reaction, and then flows into the belt-type sludge presser. The sludge is evenly distributed on the gravity dewatering zone and is Under the two-way drainage and gravity, the sludge moves with the dewatering filter belt to quickly remove the free water of the sludge. Due to the longer design of the gravity dehydration zone, the maximum gravity dehydration can be achieved. The overturned sludge enters the ultra-long wedge-shaped pre-pressing dewatering zone to slowly clamp the sludge unloaded from the gravity zone to form a sandwich-like angle layer, which is slowly pre-increased and filtered in order to make the mud layer The residual free water content is reduced to a minimum. As the upper and lower filter belts advance slowly, the upper and lower distance between the two filter belts gradually decreases, and the mud layer in the middle gradually becomes harder. The large-diameter filter roller is pre-pressed and dehydrated. , To remove a large amount of free water, so that the sludge cake smoothly enters the extrusion dewatering zone and enters the "S" squeezing section. In the "S" squeezing section, the sludge is sandwiched between the upper and lower layers of filter cloth. Several squeezing rollers repeatedly press. When the upper and lower filter belts pass through the wave path formed by the staggered rollers, the upper and lower positions of the two filter belts alternate in sequence, generating shear force on the clamped mud cake, which will remain in the sludge. Most of the moisture in the backlog is filtered out, prompting the mud cake to be dehydrated again, and finally the dry mud cake is scraped off by a scraper, and it is transported to the sludge storage place by a belt conveyor or a shaftless screw conveyor.

Phone: +86 138 1256 5699

Email: jenny@norsenep.com;sales@norsenep.com

Add: Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Add: Xibei H-Tech Park Wuxi Jiangsu China