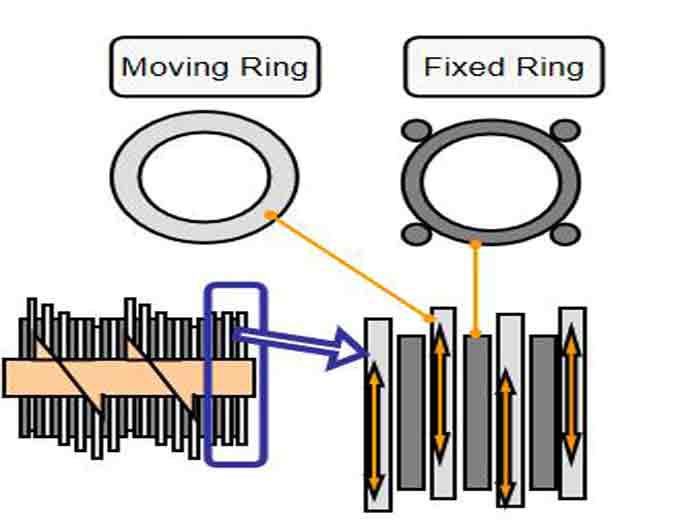

The multi-disc screw press is a new type of solid-liquid separation equipment which uses the principle of screw extrusion, through the strong extrusion pressure generated by screw diameter and pitch change, as well as the tiny gap between the moving ring and the fixed ring, to realize the extrusion dehydration of sludge.

The main body of the volute screw press is composed of multiple fixed rings and moving rings, and a screw shaft is there to form a filtering device. The front section is the enrichment section and the rear section is the dewatering section. The concentration and dewatering of the mud are completed in a cylinder, replacing the traditional filter cloth and centrifugal filtration mode with a unique and delicate mode.

The sludge is transported to the dehydration section after gravity concentration in the concentration section. In the process of advance, with the gradual decrease of the slot and pitch, and the blocking effect of the back pressure plate, the sludge generates a larger internal pressure and the volume is continuously reduced to achieve the purpose of full dehydration.

The volute screw press does not need to be cleaned a lot, which completely reduces the water consumption and the internal circulation burden. The automatic control is adopted from taking out the sludge, injection the medicine, and the discharge of the sludge cake. No need for personnel to operate the equipment, the operation will not block, the belt will not be deflected or other phenomena affecting the process safety, daily maintenance is simple, which can be continuous for 24 hours, which realizes the continuous automatic operation of sludge dewatering in the true sense.

The rotation speed of the screw shaft is about 2~3 rpm, no vibration, the noise is very small, the laminated piece has self-cleaning function, no clogging problem, only a small amount of water washing, no secondary pollution, plus sludge operating under such a slow working condition, the odor does not spread, thus creating a very good working environment.

It has the function of sludge concentration and can directly process the aerobic sludge in the aeration tank without the need of concentration and storage unit, which can reduce the overall occupation space and equipment cost of the sludge treatment facility. The working principle of the machine is related to the rate of dehydration.

Phone: +86 138 1256 5699

Email: jenny@norsenep.com;sales@norsenep.com

Add: Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Add: Xibei H-Tech Park Wuxi Jiangsu China