Multi-disc screw press fully automatic customized intelligent dewatering machine

More Videos please refer to https://youtu.be/UKl9y5Zdq5g

Brief Introduction

NORSEN’s Multi-disc screw press sludge dewatering press equipped with Multi-disc screw press technology. Dewatering with an automatic self-cleaning filter mesh enables stable constant dewatering without the need for flush water to prevent clogging. It has solved several technical problems of other similar sludge dewatering equipment including belt presses, centrifuge machines, plate-and-frame filter press have, which are frequent clogging, oil sludge treatment failure, high energy consumption and complicated operation etc.

The machine of the Multi-disc screw press sludge dewatering machine is made up by moving and fixed rings thorough screw shaft solid-liquid separator; solid-liquid separation one is divided into two parts: the concentration section and dehydration section.

Innovative Structure

The core part of the Multi-disc screw press sludge dewatering machine is clog free. The clogging of filter mesh decreases the efficiency of conventional dewatering equipments.

NORSEN's dewatering press is equipped with unique Multi-disc screw technology, which enables dewatering while automatically self-cleaning the filter mesh. This enables stable and constant dewatering to take place without depending on high pressure flushing water to prevent clogging.

This self-cleaning mechanism enables Multi-disc screw press to be ideal to dewater oily sludge, which easily causes clogging and is difficult to treat with other types of dewatering equipments.

Thickening and dewatering all in one filter drum

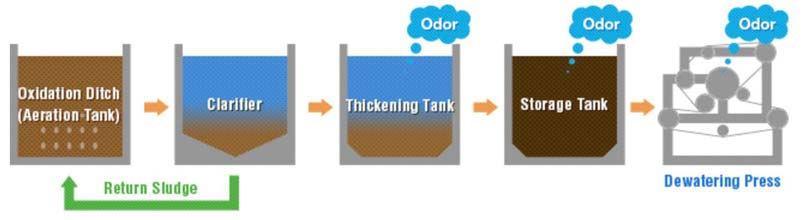

It was the common theory of dewatering process to first thicken the sludge and then dewater before the invention of Multi-disc screw press adopted the unified structure that serves two functions, thickening and dewatering in the single machinery. The secret lies in the self-cleaning mechanism. The drum filter, because of the clog-free, realizes higher speed of filtering phenomena per filtering area as compared to other methods, and the sludge is instantly thickened by gravity. For this reason, low concentration sludge of about Total Solids 0.2%, as well as thickened sludge, can be directly fed without pre-thickening.Thus, the direct feed of low concentration sludge is possible, so that the direct dewatering becomes possible from oxidation ditch (aeration tanks), many of which are introduced in small scale municipal wastewater treatment plants.

Multi-disc Screw Press Advantages

Due to the smart structure, advanced design and accurate manufacturing, NORSEN Multi-disc Screw Press has following features:

Special pre-concentrating device, wide feed solids concentration: 2000mg/L-50000mg/L

The dewatering part consists of a thickening zone and a dewatering zone. In addition, a special pre-concentrating device is mounted inner the flocculation tank. Therefore, the wastewater with rather low solids content is not a problem to Multi-disc screw press. The applicable feed solids concentration can be as very wide as 2000mg/L-50000mg/L.

Since Multi-disc screw presscan be used directly to concentrate and dewater the low-solid sludge from aeration tanks or secondary clarifiers, the users don't have to build a thickening tank or a storage tank any more while they have to when using other types of sludge dehydrators, especially the belt filter presses. Then significant civil engineering cost and floor area are saved.

Furthermore, the phosphorus emission problem caused by aeration tanks or secondary clarifiers can be well prevented.

Analysis of all kinds of dehydrated operations

Item | Multi-disc sludge dewatering press | Belt filter press machine | Decanter centrifuge dewatering machine | Frame filter press machine |

Dehydration Method | Action film spiral dehydration | Gravity and squeezing dehydration | Centrifugal dehydration | Pressure dehydration |

| Electricity Consumption | Very small | Relatively larger | Very large | Medium |

| Water Consumption | Very small | Very difficult | Small | Medium |

| Running Noise | Very small | Medium | Very difficult | Small |

| Maintaining Difficulty | Easy | Difficult | Very difficult | Easy |

| Sludge Viscosity Requirements | Lowest | Highest | Medium | Medium |

| Cake Moisture Content | about 80% | >80% | about 80% | <80% |

| Degree of Automation | High | High | High | Low |

| Workplace | Clean | Poor | Medium | Poorest |

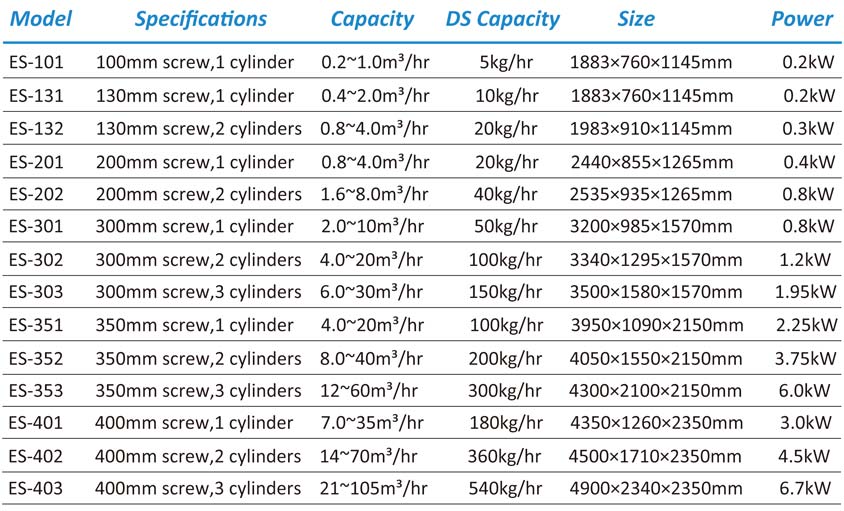

Multi-disc Screw Press Model Selection

Phone: +86 138 1256 5699

Email: jenny@norsenep.com;sales@norsenep.com

Add: Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Add: Xibei H-Tech Park Wuxi Jiangsu China